Vibration isolators for HVAC (heating, ventilation and air conditioning)

Vibration isolation for building services equipment (BSE)

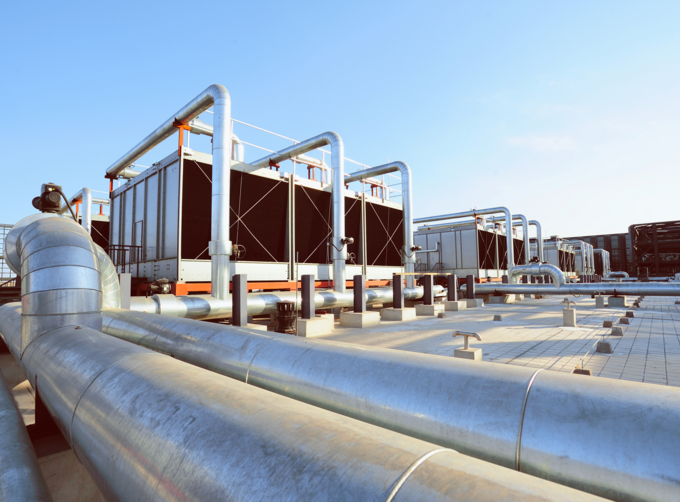

Heating, ventilation and air conditioning (HVAC) systems are an indispensable aspect of modern building engineering. HVAC installations such as air-conditioning plants, air-conditioning systems, heat pumps or other building services equipment (BSE) provide the required comfort in residential and office buildings. They are also used in the industrial environment for cooling. The vibrations caused by HVAC systems, especially when they are installed on a roof or inside a building, can have an adverse effect on the living and working environment in the adjacent parts of the building due to disruptive noise. This must be considered in BSE planning. Elastic bearings from Getzner provide the solution by reducing vibrations, structure-borne noise and secondary airborne noise and should be taken into account in the planning stage for building services equipment (BSE).

Your HVAC systems benefit from our vibration isolation solutions in the following ways:

- Quieter HVAC equipment thanks to more efficient vibration isolation

- Reduced secondary airborne noise even in critical installation locations (e.g. rooftop installation, mezzanine floors, etc.) for building services equipment

- Installation and procurement are time and cost effective

- Reduced maintenance costs

- Also ideal for use outdoors

Heat pumps

Heat pumps generate vibrations and structure-borne noise, primarily due to the compressors used. With a suitable elastic bearing, no disturbing humming sounds are produced.

Air-handling units

Modern ventilation units (AHUs) or air conditioning units are usually installed on mezzanine floors or on the roof. With an elastic mounting, vibrations caused by the fan or the air currents themselves are not audible in neighbouring rooms.

Chillers

Refrigeration machines and systems are usually installed on the roof. With an elastic mounting, strong vibrations caused by the fans and/or compressor used are not transmitted into the building structure.

Further advantages for HVAC equipment

Bearing of components inside HVAC equipment

Our Isotop® products for vibration isolation effectively reduce both structure-borne noise and secondary airborne noise. As elastic bearings inside machines and equipment, they isolate primary sound sources such as compressors or fans. This means that adjacent equipment components are not excited, and the equipment as a whole becomes noticeably quieter - an aspect that can already be considered when developing systems for building equipment.

HVAC systems installed on roofs

On buildings with building service installations on the roof, the use of elastic bearings in combination with damping materials is recommended. The damping effect is particularly relevant in the event of strong gusts of wind, for example, to prevent unwanted excitation of the installed equipment. The additional stability also helps to prevent a build-up of vibrations in the machine. This must be taken into account in BSE planning. The Isotop® products also act as vibration dampers here and prevent vibrations from becoming problematic, such as in the case of noise and vibrating surfaces in adjacent residential or commercial spaces. This is an aspect that should be considered by professional planners for building services equipment, for example when designing air conditioning and ventilation systems.

Unique properties of Isotop® products for building equipment

Bearings in the Isotop® range are specially designed for use with HVAC applications in building services equipment. However, they are also used in machine engineering in general. The advantage of these lies in the fact that the elastic properties of the Isotop® bearings can be calculated precisely. This means that optimum vibration damping is determined for each individual application in building services equipment. They also boast a consistently

reliable level of vibration isolation spanning decades. PU materials are free from softeners and exhibit no tendency towards temperature-related stiffening.

Isotop® products replace conventional rubber pads and are also used as anti-vibration mounts if required.

Contacts