Increasing passenger comfort on trains

Passenger comfort is a top priority when travelling by rail, with quiet carriages being a particularly important factor. Floating floors for rolling stock that are equipped with Sylomer® or Sylodyn® have proved particularly effective here. Noise is primarily generated when vibrations are transmitted into the carriage. This can be prevented by using effective vibration isolation – as tests at independent testing institutes in Spain and Finland have shown.

Spain

Sylomer® FR comes out on top

In the Spanish test, a phenolic resin floor panel, rubber-metal elements and our Sylomer® FR (implemented as point and strip bearings) were compared against each other. The different floor constructions with different load types were excited with an electrodynamic shaker and the vibration acceleration values were measured at the top and bottom of the construction. And the results speak for themselves: at 9.22 Hz, the natural frequency of the fully loaded Sylomer® FR is significantly lower than that of the phenolic resin floor panel (18.31 Hz) and the rubber-metal elements (12.31 Hz). Significantly better results were also achieved during testing on an unloaded floor construction (see table).

It is important to note that a lower natural frequency indicates that the bearing is more elastic and vibrations are being damped with greater efficiency. The quality factor is also a measure of the damping – the lower this figure, the more effective the system's damping.

Finland

Good performance over a wide frequency range

During testing in Finland, the damping performance of Sylomer® FR 328 was determined under various working loads. These tests made it clear that the product achieves good results for elastic isolation over a wide frequency range, particularly with high loads (230 kg/m2).

Please see our Expert Article for the relevant tables and diagrams:

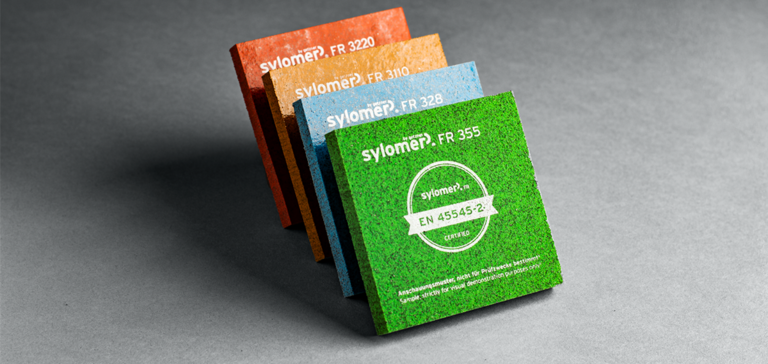

Sylomer® & Sylodyn®

Polyurethane bearings deliver added value

Sylomer® FR, Sylomer® and Sylodyn® are usually installed under the floor panel of rolling stock as point or strip bearings. Full-surface bearing with a material thicknesses of 3 mm and above is also possible and reduces the impact noise to the greatest possible extent.

While standardised acoustic testing is available, the significance of structure-borne noise is still not given sufficient emphasis. However, our experience shows that polyurethane bearings reduce sound levels by up to 7 dB (A) compared to rubber solutions and up to 12 dB (A) when replacing a rigid connection.

With their performance remaining constant over decades, the floating floor bearings are completely maintenance-free and do not compromise vibration isolation. Taking our Sylomer® FR into account during the design phase also helps to lower the floor level, reduce noise and cut the life cycle costs for the entire service life of the train. Sylomer® FR complies with fire protection standard EN 45545-2 without a heavy sandwich structure, making it an indispensable partner in lightweight construction in particular.

Product

Find out more about our Sylomer® FR

Sylomer® FR has been specially developed for use in rolling stock and meets the requirements of the fire protection standard EN 45545-2.

Contact