Optimised transition zones

for a quiet ride and infrastructure built to last

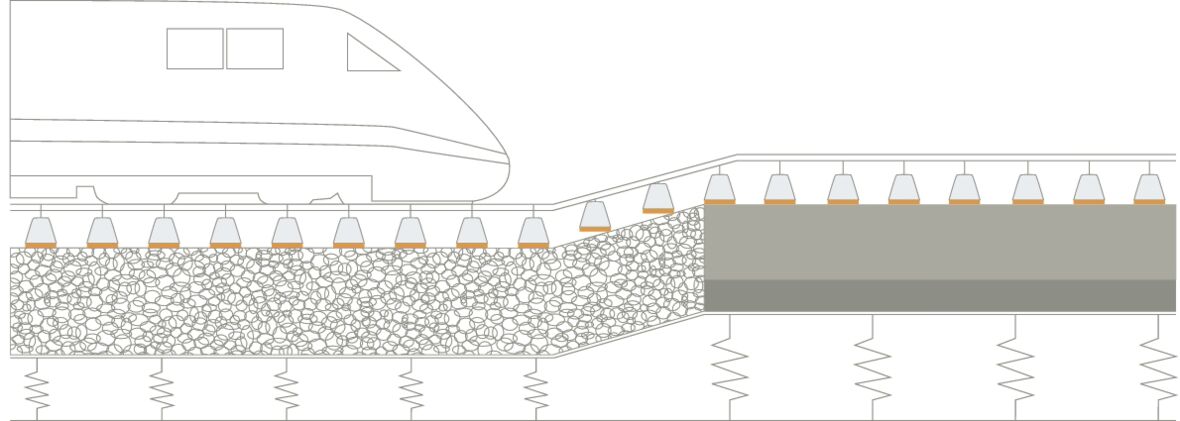

Transition areas – small sections, big impacts

In track construction, the term 'transition area' refers to places where different types of construction meet, such as where the track enters or exits a bridge. While this might sound logical enough from technical standpoint, these areas are fraught with challenges, as abrupt changes in vertical stiffness lead to dynamic load peaks. Planners, operators and maintenance teams have to contend with higher requirements in terms of design and maintenance, as these loads have a direct impact on vehicle dynamics, material wear and the service life of tracks, bridges and fixing systems. This can lead to high costs and long-term operational restrictions unless adequate countermeasures are taken. As the quality of the superstructure decreases, the resulting vibrations are increasingly transmitted to the surroundings and are perceived as a rumbling noise when trains pass over bridges, for example.

The problem: high costs due to unscheduled maintenance

Experience has shown that transition zones are critical zones that pose an increased risk of damage.

Typical problem areas can be broken down into four main areas of impact.

Safety:

- Broken sleepers or fasteners can result in derailments in extreme cases.

- Voids under the sleepers reduce ride stability.

Availability:

- Settlements in the ballast bed in front of bridges result in speed restrictions and unplanned line closures.

Costs:

- Recurring maintenance measures caused by dynamic loads (e. g. due to white spots or washouts) lead to high life cycle costs.

Acceptance:

- Visible damage, vibrations and noise disruptions have a negative impact on how passengers and neighbouring residents view the line.

Rather than occurring suddenly, these defects develop over time due to continual overloading at critical points – and often go unnoticed until it is too late.

The solution: making targeted use of elasticity

Keeping bridge transitions stable over the long term calls for sophisticated design solutions with the right amount of elasticity in the right places.

The aim here is to change the vertical stiffness continually rather than abruptly, resulting in noticeable advantages in terms of operation and infrastructure.

Safety:

- Smooth load transitions reduce impact loads and protect the bridge structure.

- Dynamic overloads – which frequently cause broken sleepers or fasteners – are prevented.

Availability and service life:

- Uniform stiffness profiles extend the service lives of ballast, sleepers and bridge structures.

- Lower maintenance requirements mean increased track availability.

Costs:

- Durable materials and reduced maintenance result in lower operating costs overall.

Acceptance:

- A smoother ride increases passenger comfort and decreases noise pollution in the surrounding area.

Elastic solutions in the spotlight – the right answer for every type of superstructure

Under sleeper pads:

- Reduce localised pressure peaks under sleepers in transition zones – the ideal way to improve load distribution directly on the bridge.

Under ballast mats:

- Create a consistent elastic ballast in front of and on bridges – to ensure loads are evenly distributed in transition areas.

Mass-spring systems:

- Ideal for demanding, highly dynamic bridge conditions – enable maximum vibration decoupling and structural protection.

Baseplate pads:

- Maintain the load-distribution qualities of the rail and reduce vibrations caused by irregularities in the wheels and track.

Getzner Werkstoffe offers powerful, customised solutions depending on the type of structure – from box and metal girder bridges to arched bridges.

The result: a quieter system – with less maintenance

The advantages of Getzner solutions:

- Optimised graduation of large variations in stiffness and deflection differences

- More uniform load distribution

- Reduced ballast loading

- Fewer voids

- Reduced shocks as the train passes over

- Less settlement

- Less wear of superstructure components

- Increased safety and ride comfort

- Less maintenance work

- Increased availability

- Extended service life

Critical weak points become a stable part of the infrastructure that is efficient, long-lasting and safe to operate.

Animation Transition Zones

Contact