Polyurethane elastomers and other materials for vibration decoupling

Getzner solutions add elasticity in areas affected by vibrations. This prevents them being transferred and becoming a problem. The critical factor is achieving precisely the right level of vibration dampening. Does the vibration need to be absorbed or redirected into the system? What different frequencies occur? How much elasticity can there be in the system without influencing its stability and statics?

Solving these challenges requires a carefully tailored range of elastic materials.

Applications

Application areas for elastomers

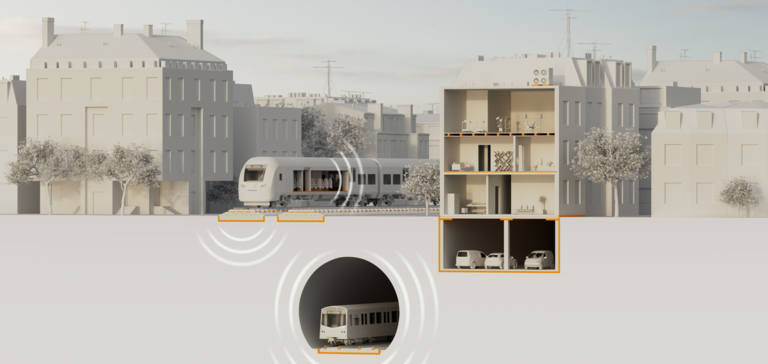

Elastomers are used wherever vibration isolation and shock protection are needed. They isolate structure-borne sound directly at the source or at the affected structure to prevent vibrations from spreading.

In the railway sector, elastomers provide effective protection against vibrations and extend service life by reducing wear.

In construction, resilient beddings protect entire buildings from incoming vibrations, while building acoustics solutions effectively isolate vibrations and noise inside.

In industrial applications, elastomers provide an effective elastic decoupling of components. They are used across a wide range of sectors and help to enhance safety, boost productivity and reduce life-cycle costs.

Special properties

Advantages of polyurethane elastomers

Polyurethane elastomers are suitable for a wide range of applications thanks to their exceptional stability and durability. They effectively reduce vibrations and can be adapted to different technical requirements. The effectiveness and durability of the materials have been tested and scientifically proven over decades.

Polyurethane plastics also stand out thanks to their high flexibility, excellent damping properties, and exceptional resistance to abrasion, chemicals and weathering. This versatility makes polyurethane elastomers the ideal solution for demanding applications where high load capacity and long service life are essential.

Polyurethane materials

The materials at a glance

Sylomer® is a polyurethane material that effectively reduces vibrations and the associated structure-borne sound thanks to a unique combination of resilient and damping properties. This material can therefore be used for a wide range of applications on railway networks, in buildings and for machine bearings.

The latest version of Sylodyn® has a higher dynamic stiffness, making it ideal for vibration isolation in extreme conditions, from high-speed railway lines to heavy machinery. The closed cellular structure makes this material ideal for use in damp conditions.

Sylodamp® is an elastic material with excellent damping properties which efficiently absorbs even extreme impact loads and provides exceptionally high energy absorption. Thanks to its consistent long-term damping behaviour, its protective performance remains unchanged over many years – ideal for safety-critical applications.

Recycled polyurethane elastomers

Thanks to the material’s exceptional properties, Getzner is committed to keeping polyurethane in the material cycle. As a result, the portfolio already includes a recycled material made from pure polyurethane: Relomer®. This granulate-based polyurethane elastomer combines resilience and damping characteristics and offers a resource-efficient alternative for many vibration protection applications – and while retaining the advantages of conventionally produced polyurethane.

Rubber for vibration isolation

Rubber is a proven material for vibration isolation and has been used in a wide range of applications for decades. Thanks to its elastic properties, rubber can effectively dampen vibrations and impacts and thus protect machinery, equipment and building structures from damaging vibrations.

Getzner’s range of elastic solutions is complemented by recycled rubber products from Isolgomma. These contain over 90% recycled material and offer an alternative to high-performance polyurethane materials.

Isotop® vibration dampers

Vibration dampers from the Isotop® range are used as convenient and easy-to-install machine bearings. They combine the superior vibration-isolation performance of Getzner polyurethane elastomers with the advantages of metal springs and components. The elastic properties of Isotop® products can be calculated precisely, enabling the optimal vibration damping to be determined for each application.

Frequently asked questions

Polyurethane, PUR, PU – what does it all mean?

Polyurethane is a versatile plastic known for its high elasticity, abrasion resistance and chemical resistance. The abbreviation PUR stands for polyurethane and is often used in technical applications. PU is the international short form and is mostly used in product descriptions and standards. All three terms refer to the same material, which is produced by a chemical reaction between a polyol and an isocyanate.

How are polyurethane elastomers made?

Polyurethane is produced by a chemical reaction between a polyol and an isocyanate, usually in the form of a diisocyanate. By carefully controlling the degree of cross-linking, materials with a range of properties can be produced – from elastic polyurethane elastomers to high-strength PU rubbers.

We manufacture elastic polyurethane products on our production lines as sheets (which can then be stored and transported as rolls) and as moulded parts for complex shapes, helping to minimise waste.

How durable is polyurethane?

Polyurethane (PUR/PU) is impressively durable. The material is highly abrasion-resistant, elastic, and can easily withstand mechanical stresses such as compression and impact.

Our polyurethane materials exhibit good resistance to oils, grease, aqueous solutions and other influences such as micro-organisms. All information on our chemical resistance can be found in the datasheet.

How is polyurethane recycled?

Mechanical recycling enables polyurethane and other engineering plastics to be remade into products for vibration isolation and shock protection. PU foams, separated by type as purely as possible, are first shredded. These ‘PU chips’ can then be easily stored for use in the next stage of the production process. The resulting PU granulate is then mixed according to a precise formulation, homogenised and blended with a binding agent. This material is then pressed into the final granulate sheet. The fine dust generated from shredding the chips is collected and fed into the chemical recycling process as a raw material.

In chemical recycling, PU materials are converted into high-quality recyclates under controlled conditions. Using an optimised energy process, we can now extract polyols that match the properties and functionality of the original source materials obtained from the fossil-based primary raw materials.

Natural frequency, vibration or loss factor – find out more in the Getzner glossary

Our glossary provides an overview and explanation of the key terms relating to vibration protection and isolation.

If you have any questions, we will be happy to help you.