Solutions for our industrial customers

In the industrial sector in particular, there is often a need for solutions tailored to customers’ requirements. Elastic elements are used in a large number of sectors to achieve the best possible results because optimised vibration protection provides safety, increases productivity and reduces life cycle costs. We provide our expertise and our unique materials and products in all applications where vibrations need to be minimised.

Elastic bearings fulfil various functions

We support OEM customers at an early stage of development to help them implement elastic vibration isolation as efficiently as possible. The goal must always be to minimise vibrations as far as possible. This ensures the best possible protection and the highest levels of comfort. It also helps to extend the service life of machines and equipment. Different aspects are prioritised depending on the application:

Damping vibrations and impacts

In vibration isolation, elastic bearings act as dampers that minimise the propagation of vibrations. This is necessary where the machines themselves cause vibrations from which the surroundings need to be protected. However, dampers can also be used as protection against sudden impacts. The damping function of our products is primarily used in the following applications:

- the HVAC (heating, ventilation and air conditioning) sector as machine bearings for various appliances such as heat pumps and air conditioning systems

- machine engineering as machine bearings for MRI machines, machines for industrial production, etc.

- the optical industry as an elastic levelling layer for polishing applications

- the sanitary sector as a bedding for jacuzzis or wet rooms

- furniture construction as dampers for drawers

- the sports and health sector as protectors or for saddle or bicycle trailer suspension

Increasing comfort

Vibrations lead to structure-borne noise, which is perceived as disruptive noise. If vibrations are minimised through precisely designed vibration isolation, this increases comfort levels significantly. Elastic bearings are used in the following sectors:

- rolling stock manufacturing as elastic floating floors in rail cars

- shipbuilding as floating floors in ships or as vibration isolation for pumps and motors

- the footwear industry as midsoles for various requirements

- special vehicle construction for interior fittings

Protecting sensitive equipment

Sensitive equipment needs to be protected against vibrations. The unique elastic properties of our products are particularly helpful here. This ability is in demand in the following areas:

- the electronics industry for sensitive microscopes, touchpads and cameras

- audio technology to protect sensitive audio equipment

- medical technology for the bearing of operating theatre microscopes or X-ray equipment

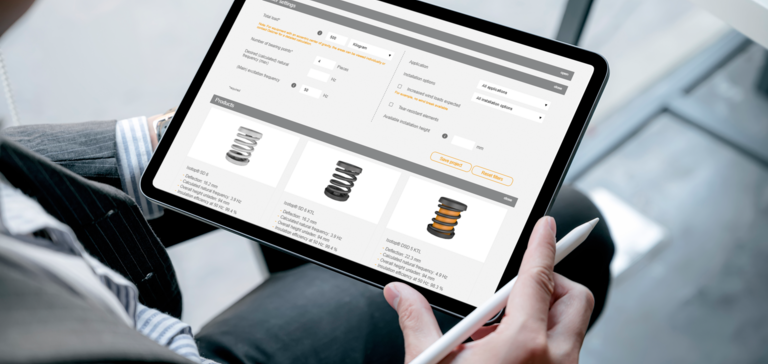

Calculation programs

How to find the best product

We provide various calculation programs for our customers.

Our EquipCalc online selection tool can help you quickly find the right Isotop® product for your application.

FreqCalc calculates the effectiveness of vibration solutions and the behaviour of an elastic bearing, whatever the disturbing frequency.

BounceCalc determines the most suitable Sylodamp® type for the effective isolation of shocks.

What we offer you

Material selection and design

Taking into account the weight, natural frequency and customer-specific requirements such as geometry or maximum installation height, we use our expertise in vibration isolation to choose the right product from our range. If necessary, we can also provide samples for initial testing. This helps to ensure that your solution is as efficient as possible.

Calculations

Our solutions offer unbeatable overall performance. Our materials have a service life of several decades – with consistent physical properties. We use calculations to show what performance you can expect from using our solutions and whether customer-specific requirements, such as the maximum natural frequency to be achieved, can be met.

Solution design and consulting

We are experts in vibration isolation, but we always keep the overall system in mind. This is how we ensure that our solutions work with maximum efficiency. During this process, we take account of design parameters as well as customer-specific requirements and specifications. We make sure that our vibration isolation solution meets your needs.

Coordinated product portfolio

Our Isotop® elements can support loads of more than 2,000 metric tons per bearing point – and the product portfolio is graded in such a way that the optimum product can be selected for every load range.

With the Sylomer®, Sylodyn® and Sylodamp® materials we developed in-house, we can meet all requirements from dynamic properties to the best possible damping. Where necessary, materials are combined to achieve the desired behaviour.